So much of what is made in the modern world can seem like magic; you buy a set of polyhedral dice for your next Dungeons & Dragons game, and wonder where exactly they came from, and how they came to be. In fact, a lot of engineering went into making the dice you now hold in your hands, and a long history.

1. Dice Were Made Even in Ancient Times

Dice have been around for centuries and have been discovered from as early as 2,000 B.C. in ancient Egypt. They were first written about in India more than 2,000 years ago, in a Sanskrit epic called the Mahabharata.

Precursors to the six-sided cube shape were the astragals, or ankle bones, of sheep and other animals. In classical Greek and Roman civilization, dice were typically made from bone or ivory, but sometimes out of metal or minerals such as rock crystal, marble, amber, and alabaster.

Four-sided dice have been around for as long as six-sided dice. The Sumerians had a game called the Royal Game of Ur, which used d4s, back in the third millennium B.C. Twenty-sided dice have also been around for millenia:

The cube-shaped d6 dice style that is common today originated in China around 600 B.C. and was introduced to Europe by the explorer Marco Polo in the 1300s. Around the year AD 1400, the numbering system for dice became standardized with the “sevens” system, where the sum of opposite sides always adds up to seven (i.e., 1 is opposite 6; 2 is opposite 5; and 3 is opposite 4.) This makes for a fairer dice roll.

Today, modern dice are usually made of plastic, although recent years have seen a surge in popularity of dice made in unusual ways or from rare materials, such as metal, wood, stone, and even 3D printing. Modern metal dice are typically made from a zinc alloy and then plated with a more expensive metal finish.

2. Some Dice are More Precise Than Others

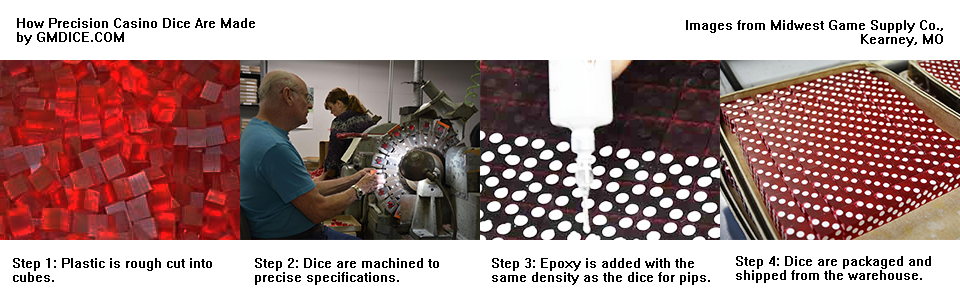

The most precise kind of dice are used in casinos for gambling games such as craps. These are manufactured to a very strict tolerance of about 1/2000th of an inch. They are machined out of blocks of plastic, and then the pips are drilled out of them, to be replaced by colored material of the same density as that which was removed. In this way, each face weighs exactly the same as every other face.

Polyhedral dice for Dungeons & Dragons or other role-playing games is not made to such exacting standards. Instead, these dice are made by injecting plastic into a pre-made mold. This leaves a small nub on the die called a sprue, which must be cut off. The dice are then coated in paint and put in a tumbler to remove the paint from every part of the dice except the indented areas where the numbers should go. This rounds the corners and edges of the dice and makes them smooth.

GameScience manufactures a line of polyhedral role-playing dice with higher precision than a normal set. They do this by skipping the tumbling phase, so the hard edges and corners are preserved. The numbers are marked with an ink pen instead, which is comparatively labor-intensive.

3. Plastic Injection Molding Is Used to Mass-Produce Dice Really Fast

Mass-produced dice are typically made with plastic injection molding. The first step of this process is to create a mold out of steel, which will have a cavity to hold the form of the dice. Typically, a mold is made of two pieces which are pressed together.

Above: An animated diagram of how a plastic injection machine works.

Creating the molds is one of the most expensive part of the dice-making process. It normally costs thousands of dollars to create each mold, so dice manufacturers usually try to re-use the same mold for many different colors, keeping all the dice the same shape.

Normally, the kind of plastic used for manufacturing dice is polymethyl methacrylate (PMMA). This is an ideal plastic because it is thermosetting, which means it turns from a soft solid or viscous liquid resin to a hard form through heating it up and then cooling it. PMMA also has a good impact strength, it is easily colored, and is heat stable.

Different kinds of pigments are added to the plastic, which is naturally clear, in order to beautify and give variety to the dice. Titanium dioxide may be used for white coloring, or iron oxides may be used for yellow, black, brown, red, or tan dice. Organic dies such as quinacridone violet, flavanthrone yellow, or pyrazolone reds may be used.

The majority of plastic dice are made in China, because plastic manufacturing is very cheap there, but plastic dice are also made in Germany, Poland, England, the United States, and other countries.

4. Dice Are Painted All Over and Then Tumbled

After the dice are molded and cooled, they are tumbled for a while to wear off the nub left over from clipping off the sprue. The tumbling machine is full of rough material that gently rubs against the hard and sharp edges of the dice, wearing them down.

This is more of an art than a science, taking anywhere from 72-96 hours. Do it too much, and the dice become too round; do it too little, and you don't get rid of the nub.

After that, it's time to paint the numbers. Painting the numbers on the dice would take forever to do by hand, so in a typical mass-production process, they are basically thrown in a big vat of paint. After that, they're tumbled again (not for as long as the first tumbling), which removes the paint from everywhere except the indented numbers.

After that, the dice get polished and inspected.

5. Fancy Color Effects Are Actually Really Hard to Do

A marbling effect can be made in the dice by adding two or more colors to the batch. This would work in a plunger-style machine, but not as well in a reciprocating screw machine, because the reciprocating screw heats up the plastic and mixes it too evenly. A marbling effect can be made with a reciprocating screw machine by modifying the screw and removing a section of flight, so it's not mixed so evenly.

A speckled effect can be made by mixing two different polymers with different melting points, so the accent color stays intact longer than the base color.

When asked why they don't make speckled dice in more colors, Donald Reents of Chessex Manufacturing had an answer you probably didn't expect:

"It’s a little bit more difficult with speckled because the powder material comes straight from the factory, and most of the colours that are made are not very bright or spectacular. There’s many shades of ivory! This is because the powder is originally made for things like toilet seats, switchplates, and many things which are not meant to come in interesting colours. But hopefully they will produce some new colours soon. When you get the powder you can’t alter the colour - so you’re limited in the number of colour combinations and possible effects."

A glitter effect can be made by adding special glitter powder to the mix.

6. Some Dice Have Been Made With Controlled Substances

Chessex had to change the coloring they used in their Chessex Borealis dice, because it started to be used in printing currency for the Euro and thus became unavailable for dice manufacturing.

Starting in 2013, the European Union came out with a new design which involved a green color-shift glitter for the numbers. To deter counterfeiting of their currency, the EU made this glitter a controlled substance. After this period, especially after 2016, the Borealis dice used a new glitter, which has more of a shimmer effect and a smaller grain.

7. You Can Make Your Own Homemade Resin Dice At Home

You can make your own dice at home fairly cheaply, using materials available at your local craft store. The first step involved is to make a mold, out of silicon, of a dice shape you want to copy. After this, a fill material is made, from resin plus any pigments, glitter, etc. you want to add, and then you inject it into the mold. You can use a pressure pot while it cures if you want to avoid air bubbles from forming.

When you remove your dice from the mold, you’ll need to sand it down smooth and then use an ink pen for numbering, like how GameScience numbers their precision dice.

Steven Braun

Some dice are also made through compression molding. Pellets are compressed using heat and pressure, which allows for certain coloring effects. Most of the dice for the game Dragon Dice are compression molded.